A cyclic crack propagation calculation consists of a series of

increments. Each increment is considered to be independent of the others. The

input for an increment is characterized by stresses and maybe temperatures for

the uncracked structure, a triangulation of the current cracks using S3 shell

elements and crack propagation material data. The following operations are

performed before the first increment:

- catalogue the nodes belonging to the field kontri(3,1..ntri) where ntri is the total number of triangles in all cracks (cattri.f).

- catalogue the edges in fields ipoed(1..nk), iedg(3,1..nedg) and

ieled(2,1..nedg), where nk is the total number of nodes in the model and

nedg the total number of edges belonging to S3-elements. An edge is

characterized by two nodes and is catalogue according to the lowest node

number of both. Entry ipoed(n1) points to a row iedg(1..3,ipoed(n1)), in

which n1=iedg(1,ipoed(n1)) is one of the nodes and n2 = iedg(2,ipoed(n1))

n1 is the other node. If more edges are present in the mesh for which

node n1 is the lowest node number, iedg(3,ipoed(n1)) points to the next such

entry in iedg, else iedg(3,ipoed(n1)) is zero. This is similar to the

structure on the left of Figure 182, except that in the present

context the number of edges is not changed within an increment and the flag

ifreeed is not needed. For each edge i the entries

ieled(1,i) and ieled(2,i) point to the triangle numbers in kontri to which

the edge belongs. For an edge belonging to only 1 triangle entry ieled(2,i)

is zero.

n1 is the other node. If more edges are present in the mesh for which

node n1 is the lowest node number, iedg(3,ipoed(n1)) points to the next such

entry in iedg, else iedg(3,ipoed(n1)) is zero. This is similar to the

structure on the left of Figure 182, except that in the present

context the number of edges is not changed within an increment and the flag

ifreeed is not needed. For each edge i the entries

ieled(1,i) and ieled(2,i) point to the triangle numbers in kontri to which

the edge belongs. For an edge belonging to only 1 triangle entry ieled(2,i)

is zero.

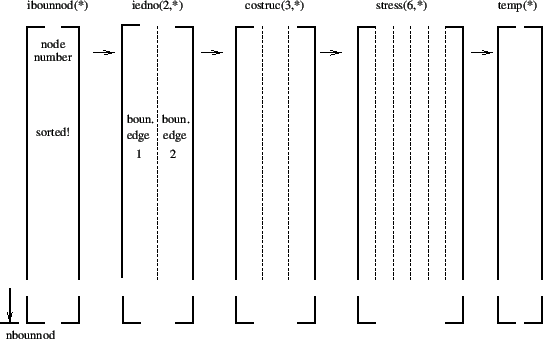

- determine the boundary edges and the boundary nodes. An edge is a boundary

edge if it belongs to only one triangle. A node is a boundary node if it belongs to a

boundary edge. The boundary nodes are stored in field ibounnod(1..nbounnod),

the boundary edges in ibounedg(1..nbounedg). The field iedno(2,1..nbounnod)

contains the boundary edge numbers to which a boundary node belongs. It is

important to distinguish between the edge numbers (1...nedg), correspondng to

the rows in

field iedg, and the boundary edge numbers (1....nbounedg), corresponding to

the rows in

field ibounedg. The fields ibounnod and ibounedg together with some other

fields, which will be discussed soon, are shown in Figure

190. The nodes in field ibounnod are sorted in ascending order.

Figure 190:

Fields for the boundary nodes and edges

|

- determine the front nodes: these are boundary nodes (i.e. on the boundary of

the crack triangulations) lying inside the structure. The way this is done

is by taken recourse to routines interpolextnodes.f and basis.f. The latter

routine interpolates the stress and temperature from the uncracked structure

onto each boundary node. In fact, basis.f is a very general routine doing

the interpolation to whatever point characterized by its global carthesian

coordinates. It looks for a location inside the master mesh which is as

close as possible to the given point and assigns the fields interpolated in this

location. Furthermore, it returns the interpolated values, the interpolation coefficients, the nodes

of the master mesh used for the interpolation, the coordinates of the

interpolation location and the distance from the

given point to the interpolation location. If this distance is really small

(a cut-off of

is used),

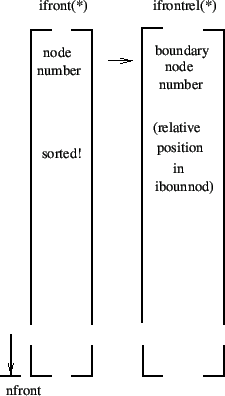

the boundary node is a front node, else it is not. The front nodes are

stored in ascending order in field ifront(1..nfront), the corrosponding

boundary node location (i.e. the row in field ibounnod) is stored in

ifrontrel(1..nfront), cf. Figure 191. The coordinates of the interpolation locations are

stored in costruc(3,1..nbounnod) and the interpolated stresses and

temperatures in stress(6,1..nbounnod) and temp(1..nbounnod), cf. Figure

190.

is used),

the boundary node is a front node, else it is not. The front nodes are

stored in ascending order in field ifront(1..nfront), the corrosponding

boundary node location (i.e. the row in field ibounnod) is stored in

ifrontrel(1..nfront), cf. Figure 191. The coordinates of the interpolation locations are

stored in costruc(3,1..nbounnod) and the interpolated stresses and

temperatures in stress(6,1..nbounnod) and temp(1..nbounnod), cf. Figure

190.

Figure 191:

Fields for the front nodes (before analyzing the

adjacency relations)

|

Notice that when using the coordinates in field costruc one obtains a

contour of the crack contracted on the structure, i.e. the boundary nodes

outside the structure are projected onto the structure.

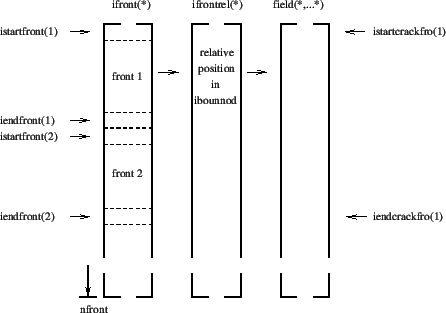

- determine the due order of the nodes in field ifront by taking the

adjacency relations into account (done in routine adjacentbounodes.f) and

adding to each non-closed front a node on either side (start and end of

the front) just outside the structure, Figure 192. Due to

this, the value of nfront will have changed if not all cracks are

subsurface cracks. The

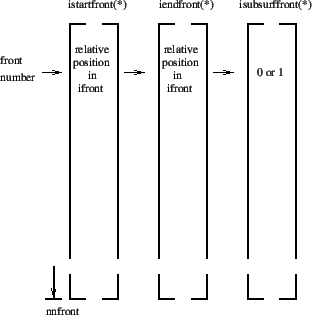

nodes are stored in clockwise direction when looking in the positive shell

normal direction. The start and end location of each front is stored in

fields istartfront(1..nnfront) and iendfront(1..nnfront), where nnfront is

the number of fronts. A zero in the corresponding field

isubsurffront(1..nnfront) indicates that the front belongs to a surface

crack, a one that it belongs to a subsurface crack, Figure

193. The field “field” in Figure 192 is

representative for a large number of fields: xt(3,*), xn(3,nstep,*),

xa(3,nstep,*), xnplane(3,nstep,*), xaplane(3,nstep,*), posfront(*),

acrack(nstep,*), xk1(nstep,*), xk2(nstep,*), xk3(nstep,*), xkeq(nstep,*),

phi(nstep,*), psi(nstep,*), xkeqmin(*), xkeqmax(*), dadn(*), wk1(*),

wk2(*), wk3(*), dkeq(*), domstep(*), domphi(*), ifrontprop(*), which will

be discussed further in this section.

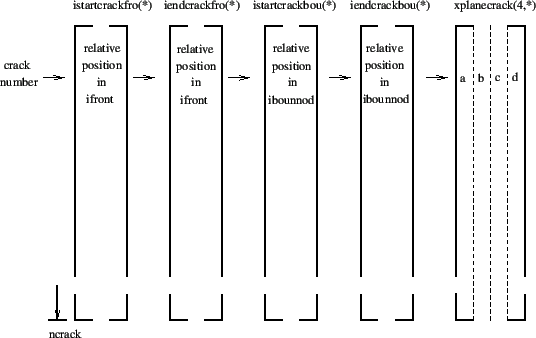

The fronts are stored crack by crack. The start and end of each crack in

field ifront is stored in fields istartcrackfro(1..ncrack) and

iendcrackfro(1..ncrack) (Figure 194), where ncrack is the number of cracks. Figure

192 applies to a case in which the first crack consists of

two fronts.

Figure 192:

Fields for the front nodes (after analyzing the

adjacency relations)

|

Figure 193:

Fields for the front characteristics

|

Figure 194:

Fields for the crack characteristics

|

At the same time, also the node order in field ibounnod is changed according

to adjacency, crack by crack. Remember that this field contains all boundary

nodes, no matter whether they belong to a front or not. Therefore, each

crack in field ibounnod is a closed contour. After changing the node order

in ibounnod all related fields in Figure 190 are also modified

appropriately as well as the entries in field ifrontrel (Figure

192), so that full consistency is guaranteed. The starting and

ending position of each crack in field ibounnod is stored in

istartcrackbou(1..ncrack) and iendcrackbou(1..ncrack).

- A local coordinate system in each node of the crack front is created and

stored in fields xt(3,nfront), xn(3,nfront) and

xa(3,nfront). This is done in routine createlocalsys.f. It consists of:

- A local normalized tangent

(field xt) to the crack front (

(field xt) to the crack front ( is the nodal position).

is the nodal position).

- a normal vector

obtained by taking the mean

of the normal vectors on the shell elements to which the front node belongs,

projecting this mean vector onto a plane orthogonal to the local tangent and

normalizing. Notice that this normal vector is pointing in the positive

direction of the shell elements (field xn).

obtained by taking the mean

of the normal vectors on the shell elements to which the front node belongs,

projecting this mean vector onto a plane orthogonal to the local tangent and

normalizing. Notice that this normal vector is pointing in the positive

direction of the shell elements (field xn).

- a normalized vector in propagation direction

(field xa).

(field xa).

- Subsequently, the crack length is calculated in subroutine

cracklength.f. In Section 6.9.25 the two different ways of

calculating the crack length are explained: CUMULATIVE and INTERSECTION.

- The method CUMULATIVE is trivial to code

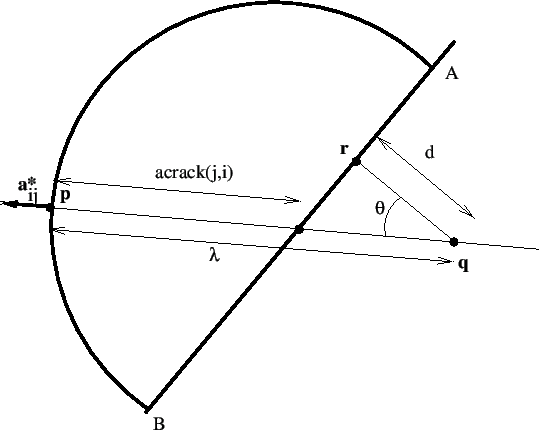

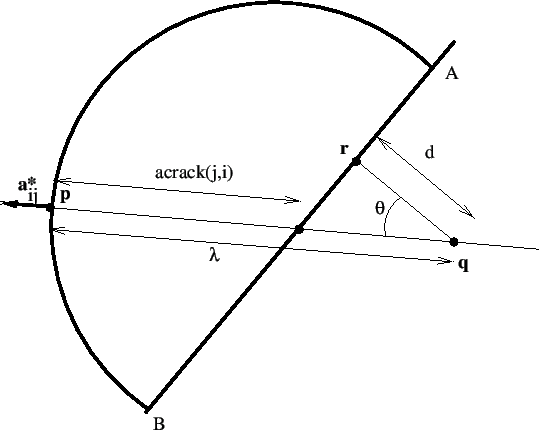

- The method INTERSECTION creates in each front node by means of the

tangential vector a plane locally orthogonal to this vector and checks

what other edge (but not immediately adjacent) along the closed crack

front is cut by this plane (using fields such as ibounedg). An edge is

cut by a plane if the substitution of the coordinates of its nodes into

the plane equation yields results with a different sign.

Figure:

Calculation of the distance of a front node from the intersection of a straight line

mit unit vector

with the free surface

with the free surface

|

The crack length is

stored in field acrack(nfront). In addition, for each front node the

relative position along the front, taking a value between 0 and 1, is also

calculated in cracklength.f and stored in field posfront(nfront).

- The crack length is smoothed and shape factors are determined in

routines cracklength_smoothing.f and crack shape.f, respectively. The

procedures are described in Section 6.9.25. For the shape factors

a field shape(3,nfront) is created, allowing for different shape factors

according to the mode. Routine shape.f is conceived as a user subroutine, so

the user can easily code his/her own shape factors.

- The stress intensity factors for mode I, mode II and mode III are

calculated in stressintensity.f and stored in fields xk1(nstep,nfront),

xk2(nstep,nfront) and xk3(nstep,nfront). The equivalent stress intensity

factor, the deflection angle and twist angle are stored in

xkeq(nstep,nfront), phi(nstep,nfront) and psi(nstep,nfront). Subsequently,

the equivalent K-factor and the deflection angle is smoothed in

stressintensity_smoothing.f. The target crack increment length is

determined in calcdatarget.f. For details the reader is again referred to

Section 6.9.25.

- The crack propagation rate is calculated in routine crackrate.f. Again,

this routine is conceived as a user subroutine. Right now, a rather simple

algorithm is implemented using the maximum equivalent K-factor for the

complete mission at a given location along the crack front. More

sophisticated procedures are conceivable using cycle extraction such as in

[73]. Output of this routine includes the crack propagation

increment da(nfront), the crack propagation rate dadn(nfront), the worst

,

,  and

and  factors wk1(nfront), wk2(nfront) and

wk3(nfront), the largest and smallest equivalent K-factor in the mission

xkeqmin(nfront) and xkeqmax(nfront), the equivalent stress intensity range

of the main cycle dkeq(nfront), the dominant step dompstep(nfront) and the

dominant deflection angle domphi(nfront). The number of cycles in this

increment is calculated based on the target crack increment and the maximum

crack propagation rate anywhere along a crack front.

factors wk1(nfront), wk2(nfront) and

wk3(nfront), the largest and smallest equivalent K-factor in the mission

xkeqmin(nfront) and xkeqmax(nfront), the equivalent stress intensity range

of the main cycle dkeq(nfront), the dominant step dompstep(nfront) and the

dominant deflection angle domphi(nfront). The number of cycles in this

increment is calculated based on the target crack increment and the maximum

crack propagation rate anywhere along a crack front.

- In crackprop.f the position of the propagated node is calculated for

each front node. The propagation is in the direction of

. At a free boundary the new crack front has to cut the

free surface, therefore at least the first and last node on a front have

to lie outside the structure. This is checked by the interpolation routine

basis.f. If e.g. the first node is inside the structure, the line segment

connecting the node with its propagated position is rotated in steps of

. At a free boundary the new crack front has to cut the

free surface, therefore at least the first and last node on a front have

to lie outside the structure. This is checked by the interpolation routine

basis.f. If e.g. the first node is inside the structure, the line segment

connecting the node with its propagated position is rotated in steps of

until the propagated node lies outside the structure. In

order for this procedure to work under all circumstances a minimum crack

propagation increment of

until the propagated node lies outside the structure. In

order for this procedure to work under all circumstances a minimum crack

propagation increment of

[L] is defined.

[L] is defined.

Notice that for this procedure to work properly, the first and last node of

the actual front have to lie on the intersection of the front with the free

surface. This is not necessarily guaranteed by using the field

costruc. Indeed, the values in costruc are determined in routine basis.f. If a

node is inside the structure, costruc contains its actual coordinates, if it

is outside the structure, it contains the coordinates of its projection onto

the free surface. If the front makes an angle with the free surface which is

significantly different from 90 , the projection will not lie on the

front. Therefore, for the end nodes a correction is made similar to Figure

195: assuming

, the projection will not lie on the

front. Therefore, for the end nodes a correction is made similar to Figure

195: assuming

is the crack front,

the projected position

is the crack front,

the projected position

is replaced by

is replaced by

acrack(i)

acrack(i) .

.

The propagated node numbers are stored in

ifrontprop(nfront).

- Subsequently, on the new crack front consisting of the propagated nodes

new equidistant nodes are created. The distance between these nodes is the

mean distance between any two nodes on the initial front and is stored in

charlen(1..nnfront). The equidistant nodes are stored in fields

ifronteq(1..nfronteq), istartfronteq(1..nnfront) and

iendfronteq(1..nnfront), which are completely analogous to ifront,

istartfront and iendfront.

- Finally, the mesh describing the crack is extended by the new

increment. To this end new elements are generated connecting the nodes on on

the actual front

,

,  , ...,

, ...,  with the propagated equidistance nodes

with the propagated equidistance nodes  ,

,

, ...,

, ..., . First, for each node

. First, for each node  the node among the actual nodes

the node among the actual nodes

,

,  .... is looked for which is the closest neighbor (using routine

near3d.f). Let us call

this node

.... is looked for which is the closest neighbor (using routine

near3d.f). Let us call

this node  . Then, the algorithm for the triangulation is as follows:

. Then, the algorithm for the triangulation is as follows:

- set

- start loop

- create a triangle

,

,  and

and  .

.

- If

, then let's say that

, then let's say that  (c naturally exists, since

(c naturally exists, since  belongs to the actual front). Then, create triangle

belongs to the actual front). Then, create triangle  ,

,  ,

,

, triangle

, triangle  ,

,  ,

,  .. until triangle

.. until triangle

,

,  ,

,  where

where

. Set

. Set  to

to  .

.

- if

and

and  both belong to the last created triangle, exit.

both belong to the last created triangle, exit.

- set

to

to  .

.

- cycle loop

Notice that shell elements are expanded in CalculiX. Therefore, at the start

of routine crackpropagation.c the crack surfaces are really modeled by

6-node wedge elements. Therefore, the extension of the crack is also modeled

by wedges with a very small thickness.

- store the incremental results into global fields (wk1glob,....)

- start a new increment

After all increments have been calculated (or if nowhere along the crack front

propagation occurred or if  was exceeded anywhere along the crack

fronts) the results are stored in frd-format.

was exceeded anywhere along the crack

fronts) the results are stored in frd-format.

![]() , the projection will not lie on the

front. Therefore, for the end nodes a correction is made similar to Figure

195: assuming

, the projection will not lie on the

front. Therefore, for the end nodes a correction is made similar to Figure

195: assuming

![]() is the crack front,

the projected position

is the crack front,

the projected position

![]() is replaced by

is replaced by

![]() acrack(i)

acrack(i)![]() .

.

![]() was exceeded anywhere along the crack

fronts) the results are stored in frd-format.

was exceeded anywhere along the crack

fronts) the results are stored in frd-format.